- Home Page

- Company Profile

-

Our Products

- Pneumatic Cylinders

- Alloy Steel Festo Cylinder

- Low Friction Double Acting Air Cylinders

- Pneumax Ecolight Series Pneumatic Cylinder

- Pneumatic Air Cylinder

- Square Type Double Acting Cylinder

- A 10-11 Janatics Cylinder

- Compact Guided Cylinder

- Aluminium Festo Cylinder

- Compact Pneumatic Cylinder

- Double Acting Compact Cylinder

- Cylindrical nipples for compensators

- Pipes Fittings

- Boiler Spares Parts

- Air Gas Regulators

- Hydraulic Pressure Gauges

- Hydraulic Hose Pipe

- Misting Nozzle

- PU Pipe

- Pressure Transducer

- Coiled Hose

- Syphon Pipe

- Gauge Cock

- Cylindrical Filter Element

- Pneumatic Seal Kit

- Compressed Air Piping System

- Pneumatic Pipes Fittings

- Pneumatic Air Cylinders

- Pneumax Pneumatics Products

- Pneumatic Air Gun

- Pressure Gauge

- Air service units

- Double filter

- Oil removal filter

- Carbon Filters

- Panel regulators

- Panel mounted pressure regulator with pressure gauge built into the adjusting knob

- Filter regulators

- Piloted pressure regulators

- Pressure regulators for manifold

- Oil mist lubricator

- Progressive start-up valve

- Air intake

- Pressure switch

- Air intake with pressure gauge

- Supply and discharge valve single

- Coalescing filters

- Filter regulators

- Progressive start-up valve

- Air Intake

- Fixing bracket

- Fixing bracket for regulators

- Pressure Switch complete with adapter

- Pressure gauge

- Fixing bracket for pressure regulator

- Fixing bracket

- Assembling kit for manifold regulators

- Shut-off valve

- Pneumatic shut-off valve

- Filters regulators

- 1700 INDUSTRIAL FIELDBUS

- PRESSURE REGULATORS WPR SERIES WIDE PRESSURE RANGE

- 1700 standard

- Pressure switches Series DS

- Pressure gauges Series DS

- Vacuum Technology

- Standard round suction cup Series 1900

- Cup-style round suction cup Series 1900

- Round flat suction cup Series 1900

- Long bellows suction cup Series 1900

- Flat round bellows suction cup for plastic film Series 1900

- Round flat suction cup with touch valve Series 1900

- Long bellows suction cup for bags Series 1900

- High friction round suction cup Series 1900

- High friction round bellows suction cup Series 1900

- Standard round suction cup made of polyurethane Series 1900

- Oval high-friction bellows suction cup Series 1900

- High friction oval suction cup Series 1900

- Standard level compensator G18 internal and external spring Series 1900

- Standard level compensator G14 internal and external spring Series 1900

- Anti-rotation level compensator G38 internal spring Series 1900

- Sleeves for antirotation level compensators

- Modular multifunction vacuum generator 19M14.M.09.ME

- Modular multifunction vacuum generator 19M14.M.12.ME

- Modular multifunction vacuum generator 19M14.M.15.ME

- Modular multifunction vacuum generator 19M14.M.18.ME

- Multifunction vacuum generator 19M14.M.09.SE

- Generatore di vuoto multifunzione 19M14.M.12.SE

- Multifunction vacuum generator 19M14.M.15.SE

- Multifunction vacuum generator 19M14.M.18.SE

- Mini solenoid valve 15 mm N221.0F

- Connector 315.11.00

- Closing plate N221.00

- Digital vacuum switch DS.30.C.C.F8

- SERIES PG HIGH FLOW RATES FOR COMPRESSED AIR AND VACUUM

- Solenoid-Spring-Self feeding 779V.32.0..M2V

- Pneumatic-Spring 779V.32.11

- Solenoid-Spring 776V.22.0.1C

- Manual regulator for vacuum Series 1700

- Series 1900 air-vacuum version SIZE 0

- SERIES 1900 AIR-VACUUM VERSION SIZE 1

- SERIES 1900 AIR-VACUUM VERSION SIZE 3

- SERIES 1900 VACUUM-VACUUM VERSION SIZE 1

- Suction Cup Support 19SP.T

- Mini digital vacuum switch DS.10.V.B

- Digital vacuum switch

- Digital vacuum gauge

- Digital battery vacuum gauge

- Panel-mounted digital vacuum switch

- Vacuum Gauge

- Pneumatic vacuum switch

- Electromechanical vacuum switch

- Line filters

- Vertical filters

- High efficiency silencers

- Air Blow Gun

- Pneumatic actuation

- Series 1200 Rolled end covers (MIR)

- Series 1200 Rolled and covers (MIR-INOX)

- Series 1200 Steel line

- Series 1200 Threaded end covers cylinders

- Series 1200 TECNO-MIR

- Series 1200 Special performance (1213-1273)

- Series 1325-1326-1345-1347

- Series ECOFLAT

- Hydraulic speed controll check cylinders

- Short stroke compact cylinders

- Compact Cylinders Europe

- Compact Cylinders ECOMPACT-S Series

- Arbitrary mount cylinders

- Guide cylinders

- Twin rod slide units

- Pushpull twin rod slide units

- Slide Cylinders series 6600

- Guided compact cylinders - 6100-6101-6110 Series

- Rodless cylinder

- Rodless cylinder 016

- Rodless cylinder

- Single rack

- Rotary actuators Series 1330-1331-1332-1333

- Vane type rotary actuators

- swing clamp cylinder

- Parellel style - Pneumatic grippers Wide opening

- Pneumatic grippers angular

- Pneumatic grippers, angular 180 Angular

- 3 fingers parallel style Pneumatic grippers

- Parellel style - Pneumatic grippers

- Pneumatic grippers, angular 180 Angular - rack and pinion style

- Limit Switches

- piston rod lock devices

- Linear guiding units

- Series 6900 Dampers

- Solenoid-Spring-External feeding 779V.32.0..M2

- Green line pneumatic fittings

- PU Connector

- IPCVC-G Straight male parallel unidirectional fitting

- IPCVF Tapered male female unidirectional fitting

- IPCVF-G Parallel malefemale unidirectional fitting

- IPCVU Unidirectional straight connector

- ISPC Straight male tapered stop fitting

- ISPC-G Straight male parallel stop fitting

- ISPU Stop fitting straight connector

- ISPL-G L male parallel stop fitting

- ISPL L male tapered stop fitting

- 504 Hand slide valve

- 505 Hand slide valve

- 503 Brass quick exhaust valve

- JXQ Heavy Duty quick exhaust valve

- UR Tablet for exhaust valve

- ISE-G VSR + RFV parallel thread

- ISE VSR + RFV taper thread

- JAQ Cube quick exhaust valve

- 101 Parallel nipple

- 102 Taper nipple

- 102P3 Nipple (taper) 3 pieces

- 104Z Parallel reducer

- 104 Taper reducer

- 103 Sleeve

- RIPUL In-line output manifolds

- RIP4V Aluminium cross manifold

- RIPUC Opposite output manifolds

- PSVA Metal tube cutter

- TPT Technopolymer tube cutter

- MORS Terminals

- TPU Polyurethane tube

- PA12 Polyamide tube

- TPA Polyurethane tubeCopolyester ALLOY SOFT

- SSN-G Swivel flow regulator for cylinder

- T28 Orientable flow regulator for valve

- T29 Orientable flow regulator for cylinder

- T30 Orientable bidirectional flow regulator

- T30P Swivel bidirectional flow regulator

- T29P Swivel flow regulator for cylinder

- T28P Swivel flow regulator for valve

- T31 Flat flow regulator

- TB28 Orientable flow regulator for valve

- TB29 Orientable flow regulator for cylinder

- TB29P Swivel flow regulator for cylinder

- TB30 Orientable bidirectional flow regulator

- T29GS Speed controller for cylinders with lock cap

- TB30P Swivel bidirectional flow regulator

- SSN-G Swivel flow regulator for cylinder

- TC Plastic tube cutter

- 301 Taper straight male adaptor

- 301Z Parallel straight male adaptor

- 302 Straight female adaptor

- 305 L taper male adaptor

- 304 Bulkhead connector

- 303 Straight connector

- TL L parallel male adaptor

- 305F Female L adaptor

- 306 L connector

- 309 T connector

- 308 Off-set T adaptorva

- 307 Central T adaptor

- 201 Taper straight male adaptor

- 201Z Parallel straight male adaptor

- 202 Female straight adaptor

- 205 L male adaptor

- 204 Bulkhead adaptor

- 203 Straight connector

- 206 L connector

- 207 Centre male t adaptor

- 208 Off-set male t adaptor

- Industrial Valves

- SS Industrial Globe Valve

- 3 Way Mixing Diverting Control Valve

- Supply and discharge valve double

- Actuator Ball Valve

- Stainless Steel Foot Valve

- Manifold unit

- Filter pressure regulator + Lubricator

- Angle Seat Valve

- Pneumatic Ball Valve

- Hydraulic Control Valves

- Brass Ball Valves

- Filter + Pressure regulator + Lubricator

- Brass Gate Valve

- Electric shut-off valve

- Equivalent Gas Solenoid Valve

- Cast Iron Ball Float Steam Trap Valve

- 1700 miniaturized

- Diaphragm Solenoid Valve

- Steam Globe Valve

- Janatics Solenoid Valves

- Dynamic drier

- Brass Check Valve

- SS Pneumatic Control Valve

- Butterfly Cast Iron Valve

- Assembling kit

- Pneumatic Flow Control Valve

- Metal Diaphragm Valve

- 2-2 Way Direct Acting Solenoid Valve

- Manifold pressure regulators

- Safety Metal Valve

- Shut off valves

- Feed Check Valve

- Directional Control Valve

- Safety Relief Valve

- Standard level compensator M5 internal spring Series 1900

- Three Way Ball Valve

- Sleeves for antirotation level compensators

- Cast Iron Pneumatic Control Valve

- Standard level compensator G12 Series 1900

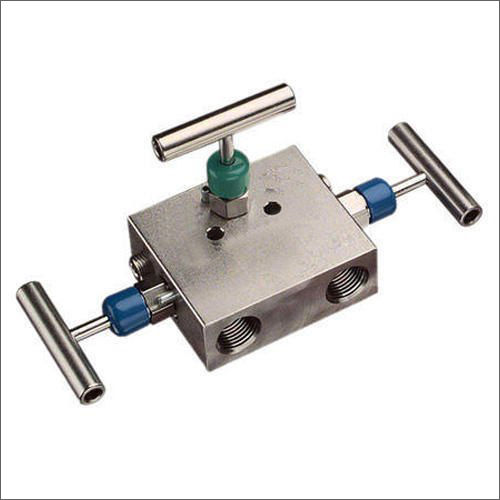

- 10 Bar Manifold Valve

- Plastic Solenoid Valve

- Ball Valves

- Stainless Steel Check Valve

- Pneumax Solenoid Valve

- Mini Ball SS Valve

- SS Actuator Ball Valve

- Steam Solenoid Valve

- Stainless Steel Hand Valve

- Actuated Globe Control Valve

- Brass Gas Solenoid Valve

- Hand Rotary Valve

- 3 Way Pneumatic Control Valve

- Shut-off valves 19E.A.00.MF

- Shut-off valves with controlled leakege loss

- Non Return Valve

- Pneumatic Valves

- Brass Diaphram valve

- Pneumatic Cylinders

- Contact Us

Call us now07313726933

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese